FORM

PROJECT 1: VESSELS

Students were assigned to make a vessel using the tools in the fabrication lab and laser cutters. We had a short lecture on the meaning of a vessel and its history. They did the technical drawings of their vessels in illustrator. They laser-cut their vessel using box maker tools or other tools. Finished it using various other tools at the lab. They were asked to finish them well using various wood finishing methods from painting, and sanding to staining and filling the gaps. The vessel had to have a lid and handles.

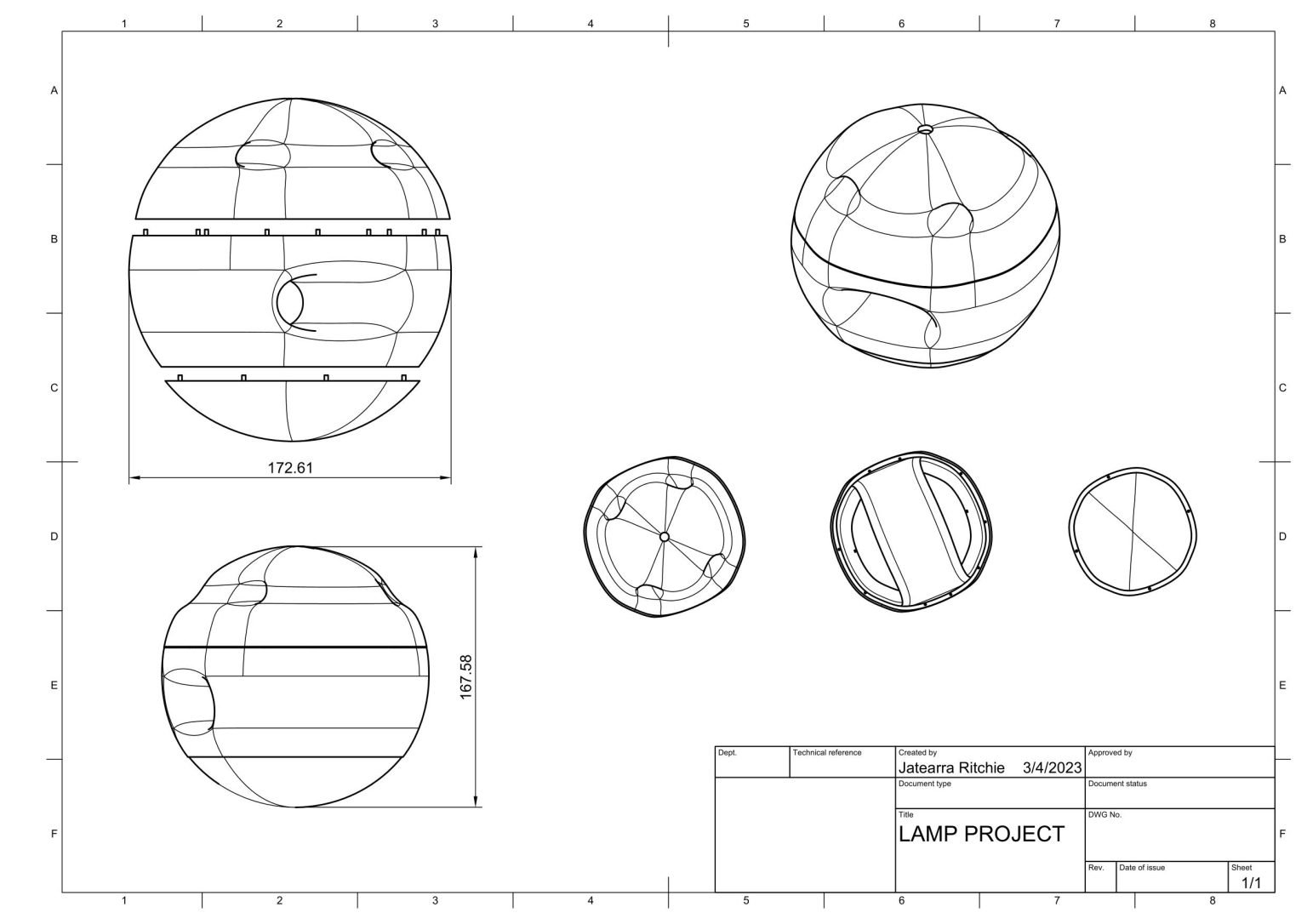

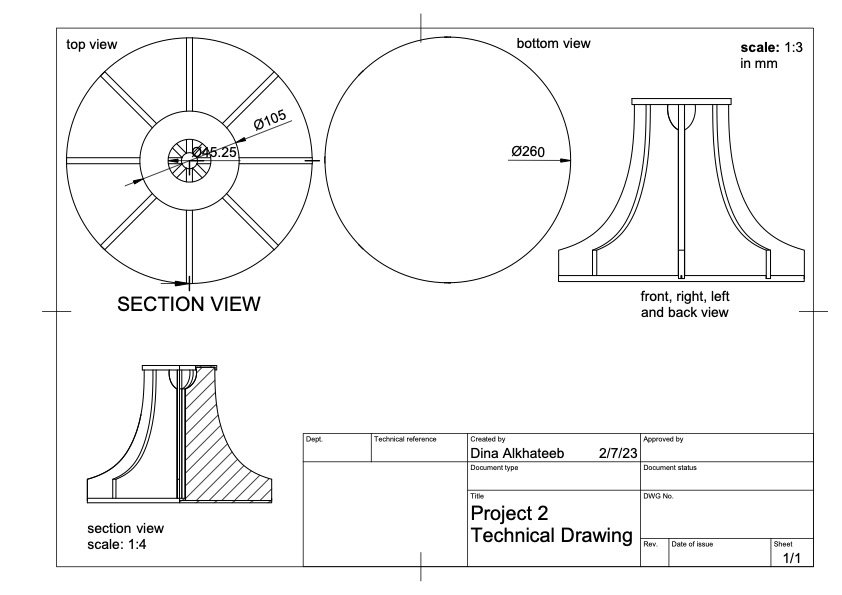

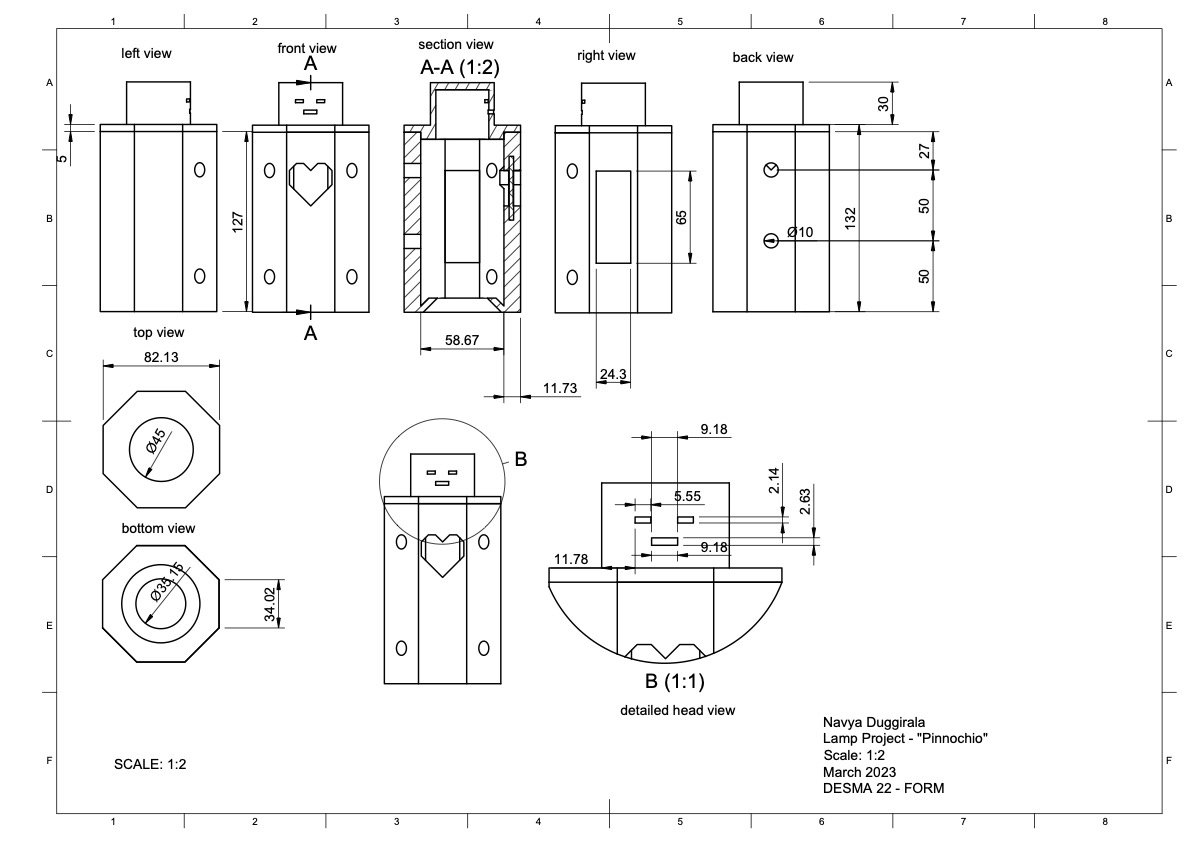

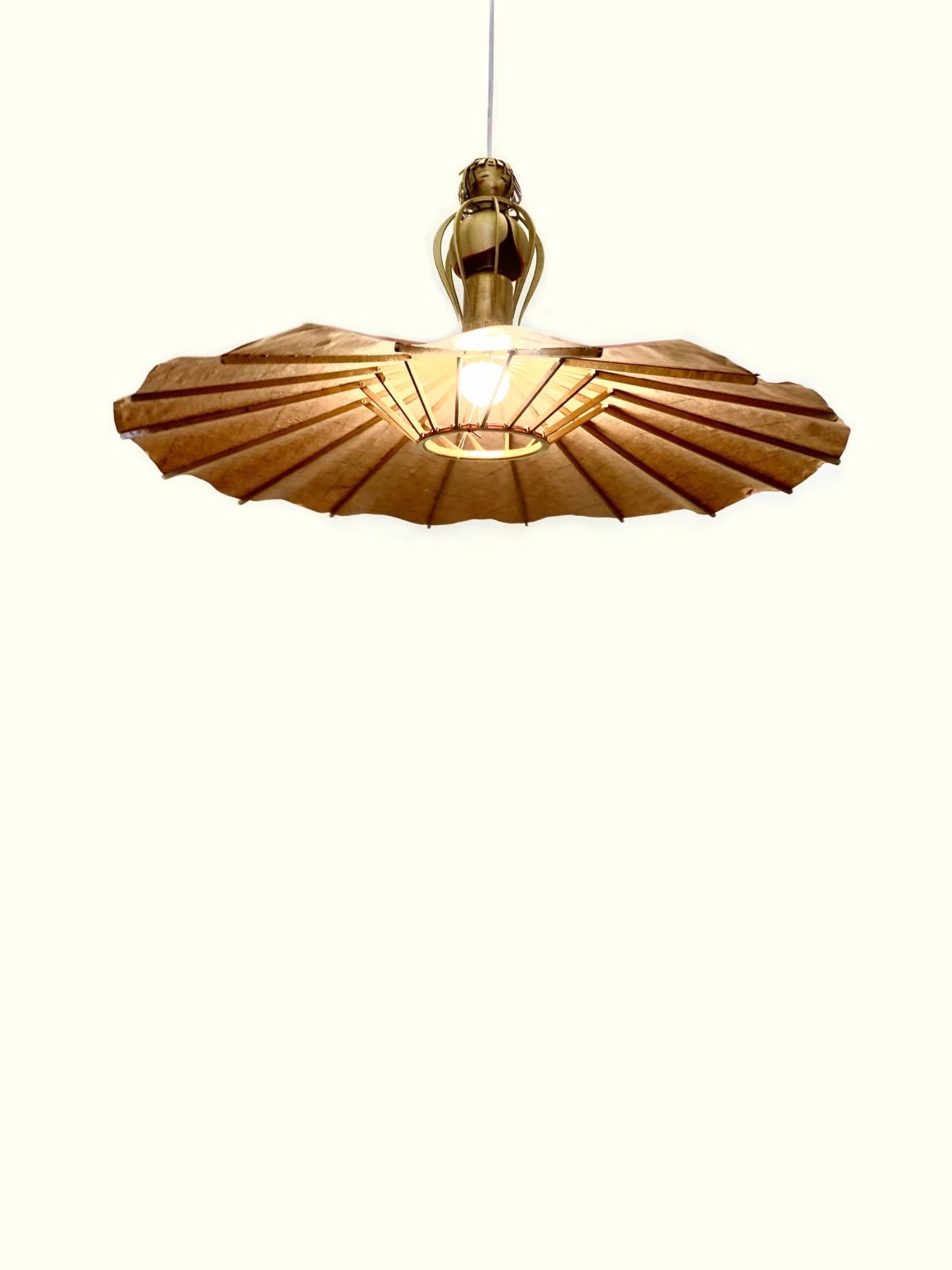

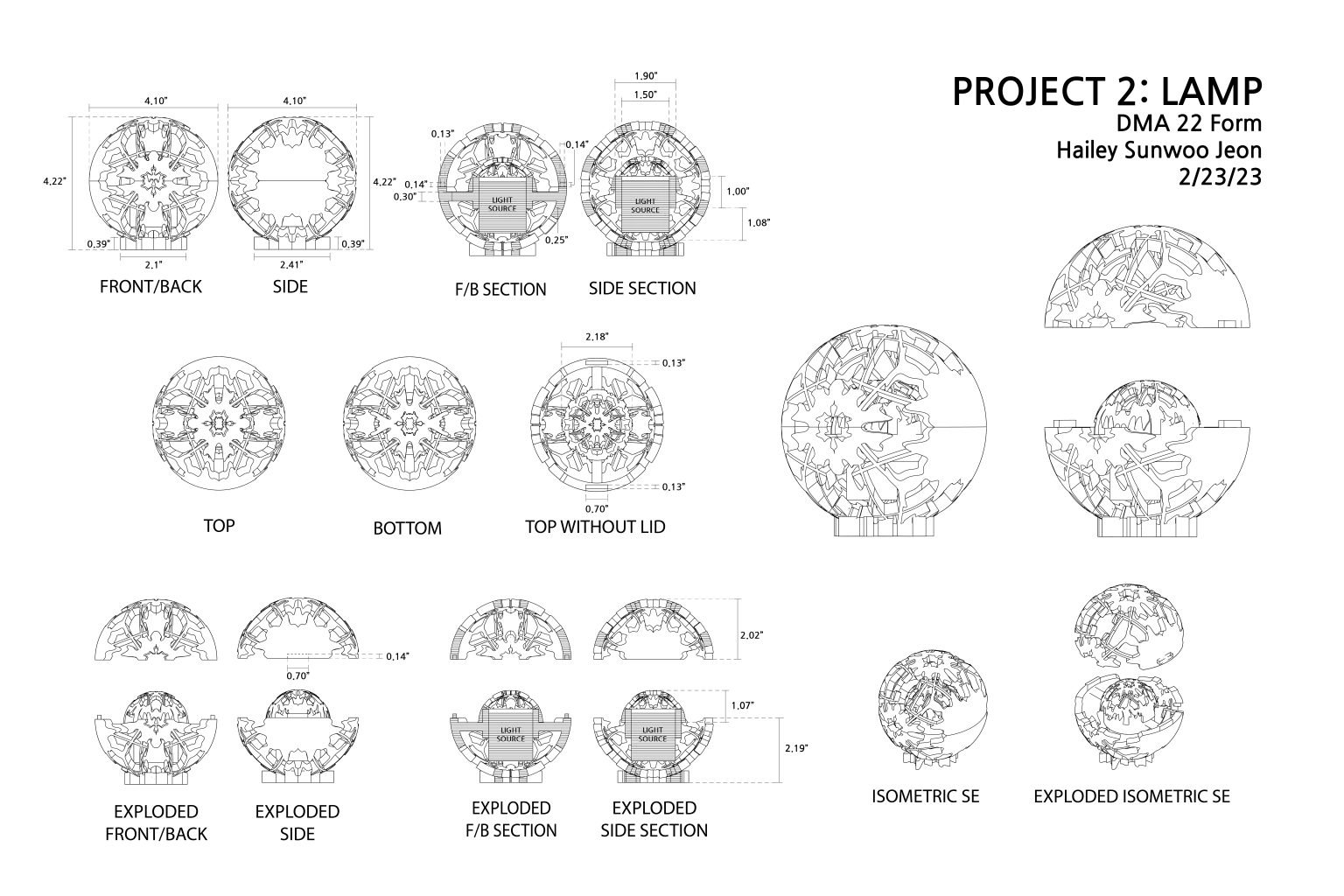

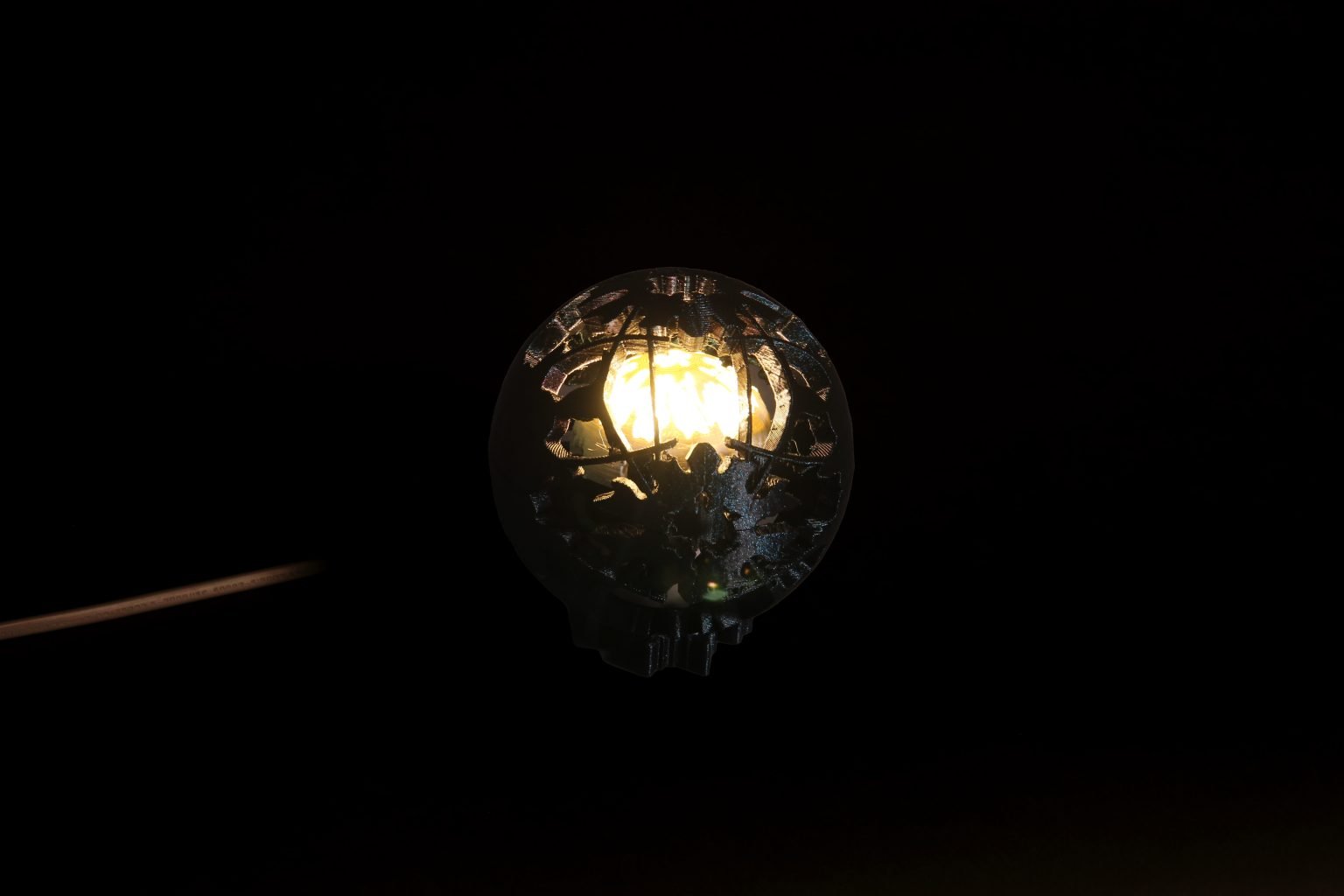

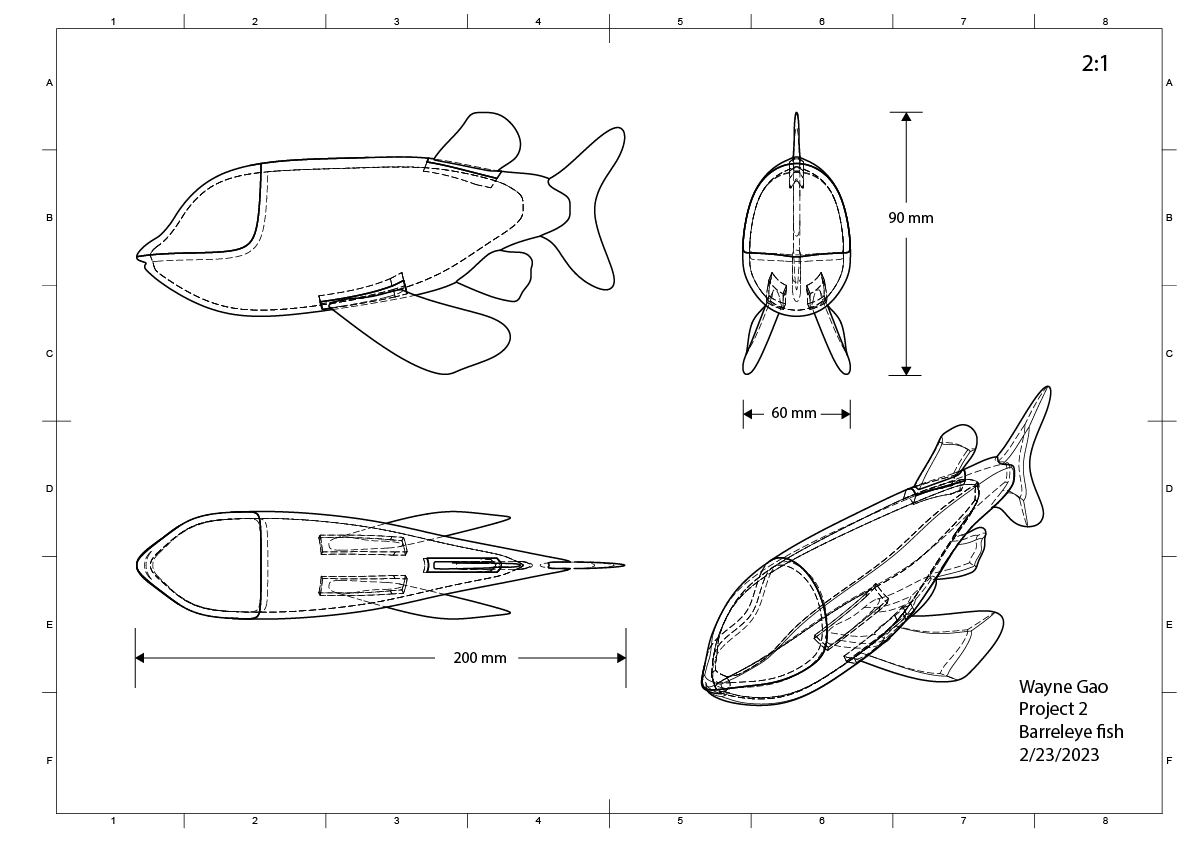

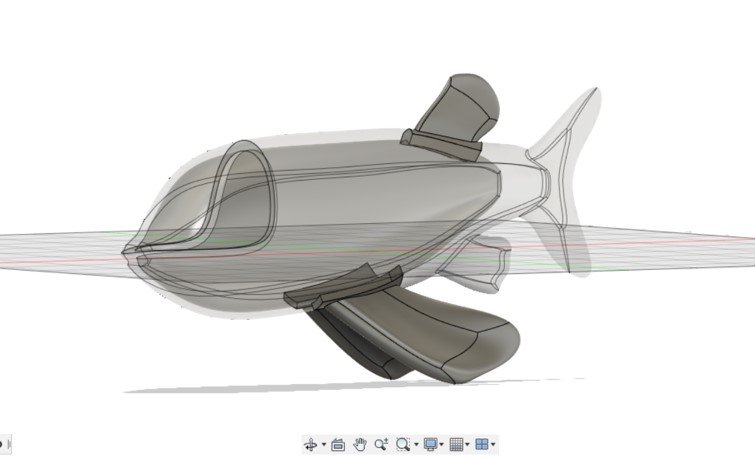

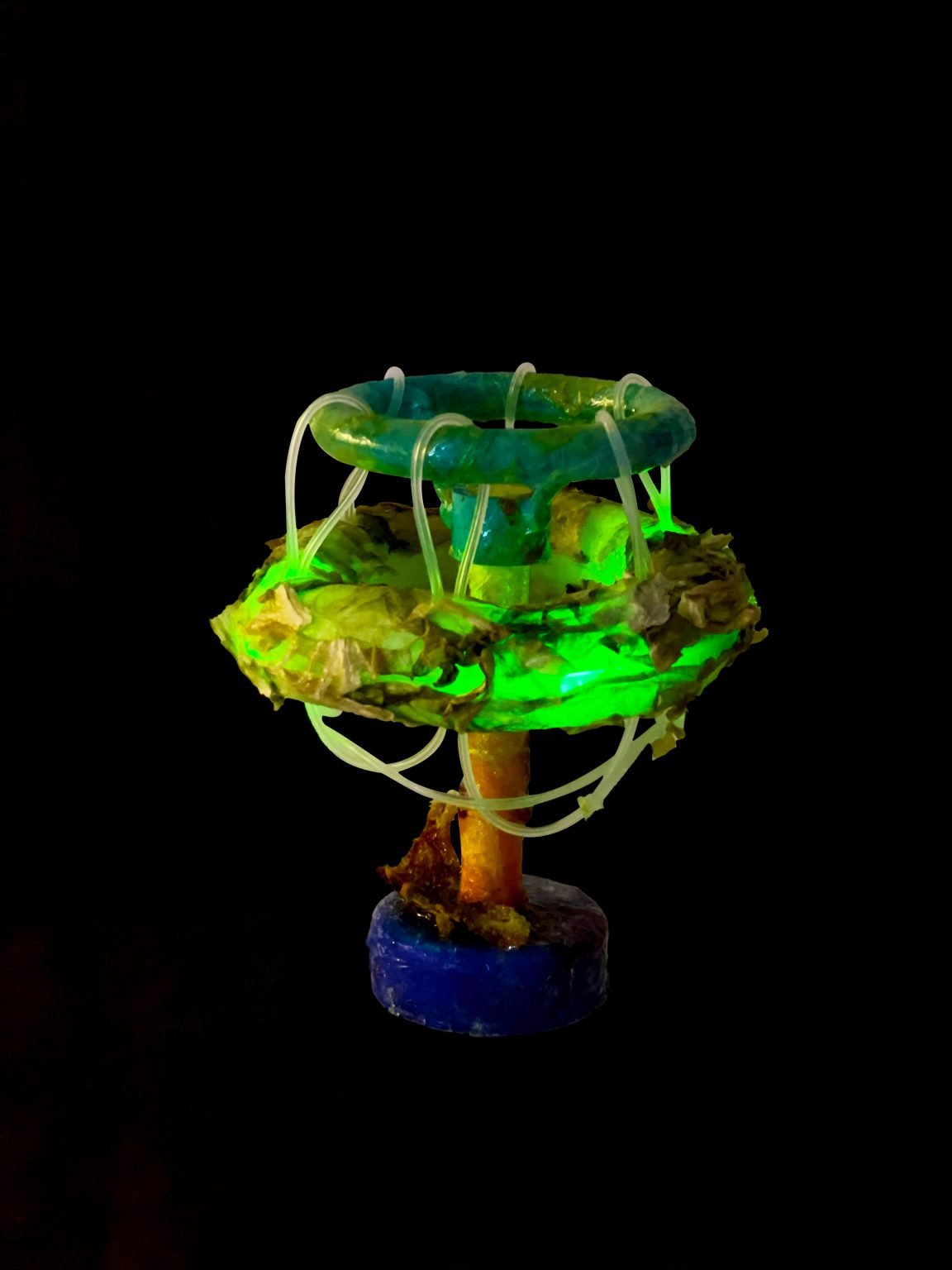

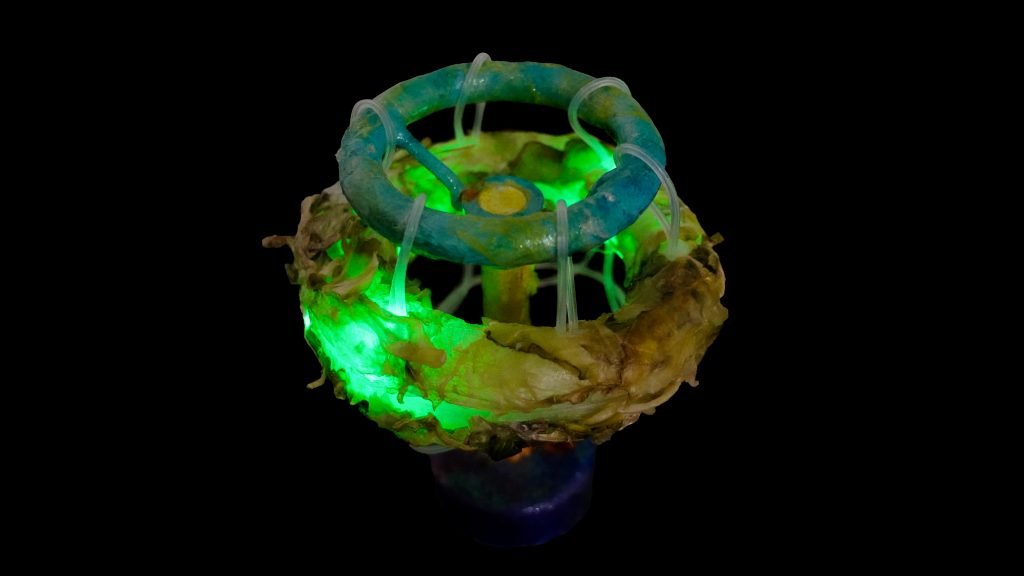

PROJECT 2 LAMP DESIGN

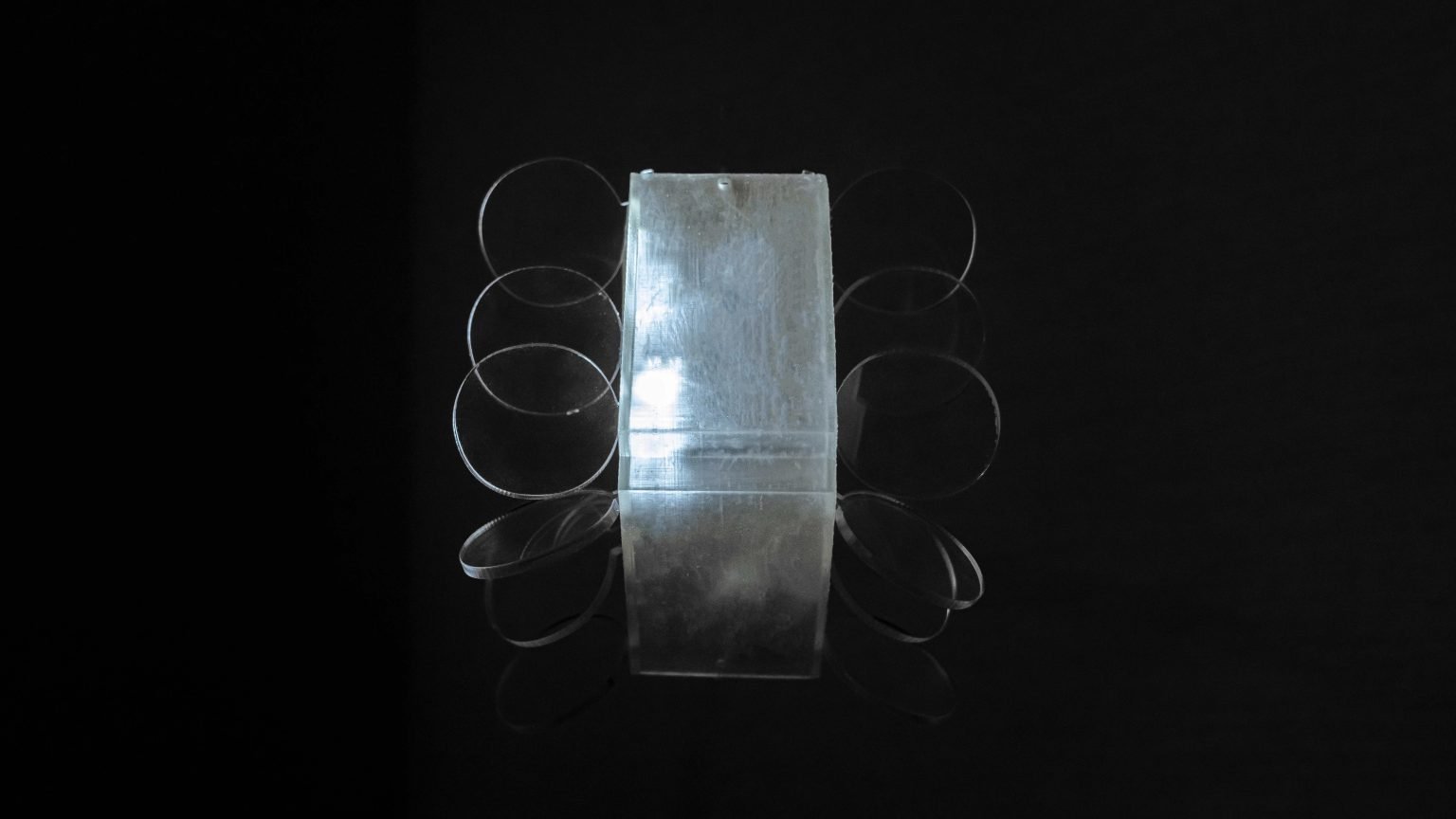

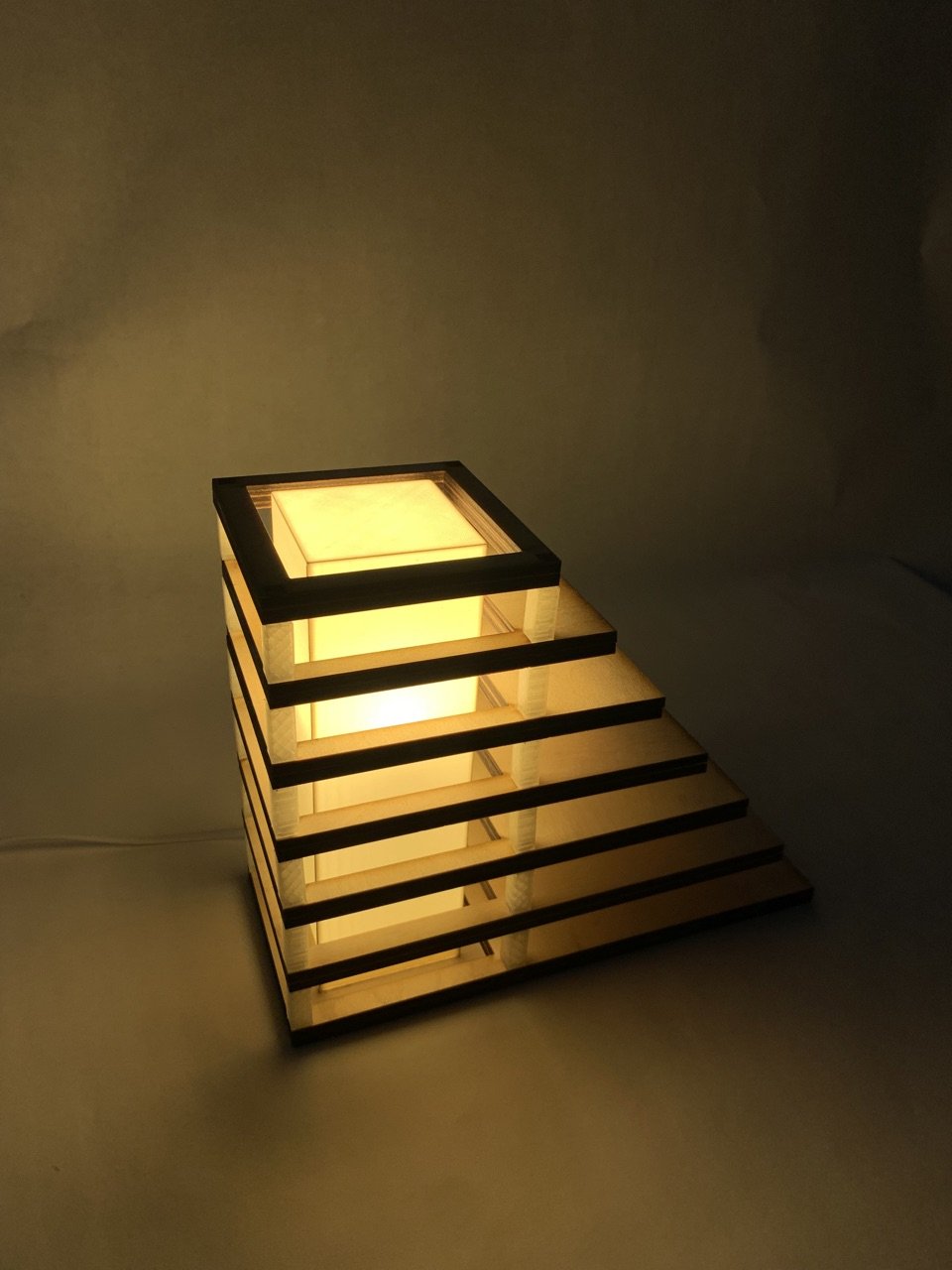

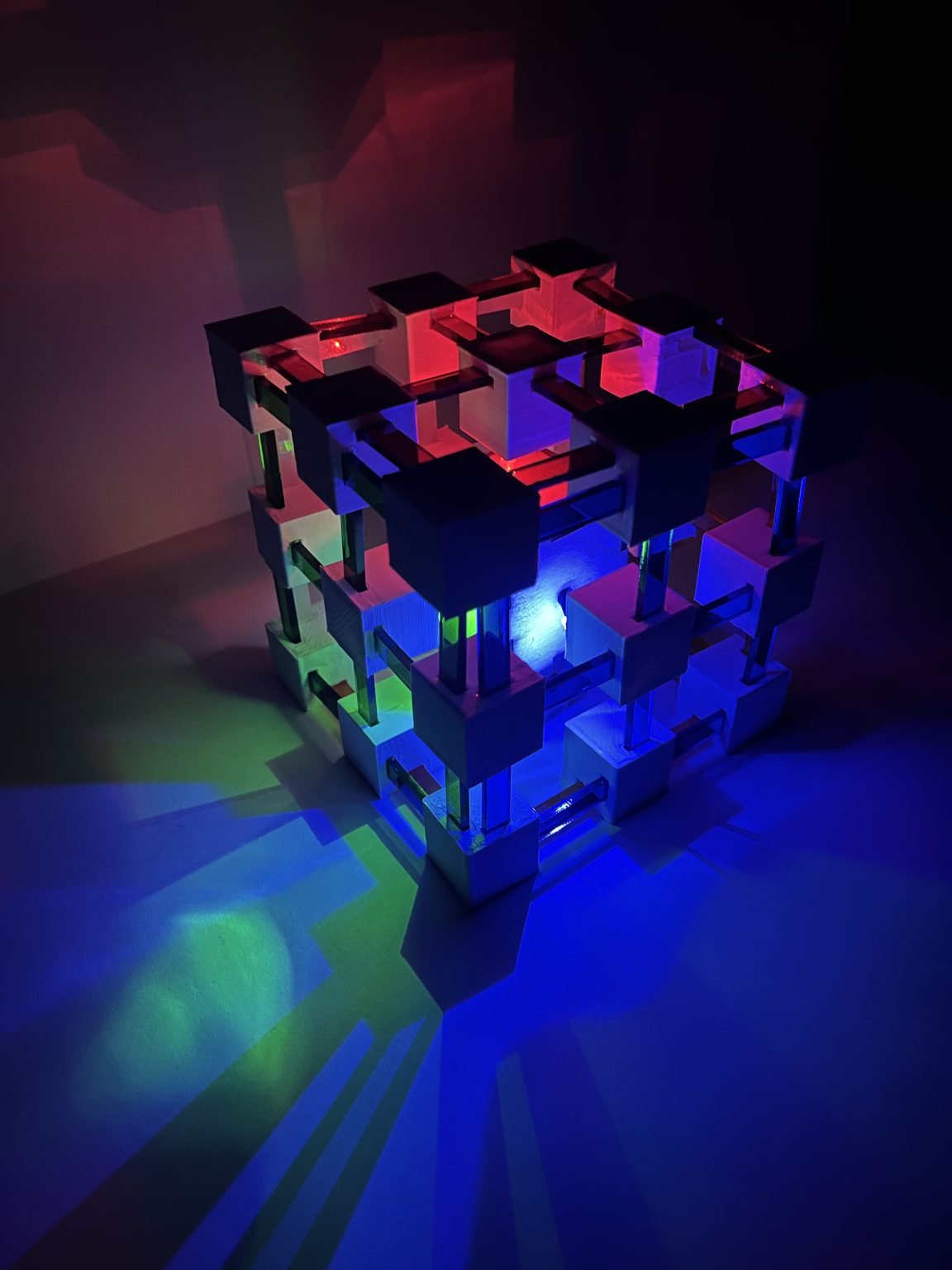

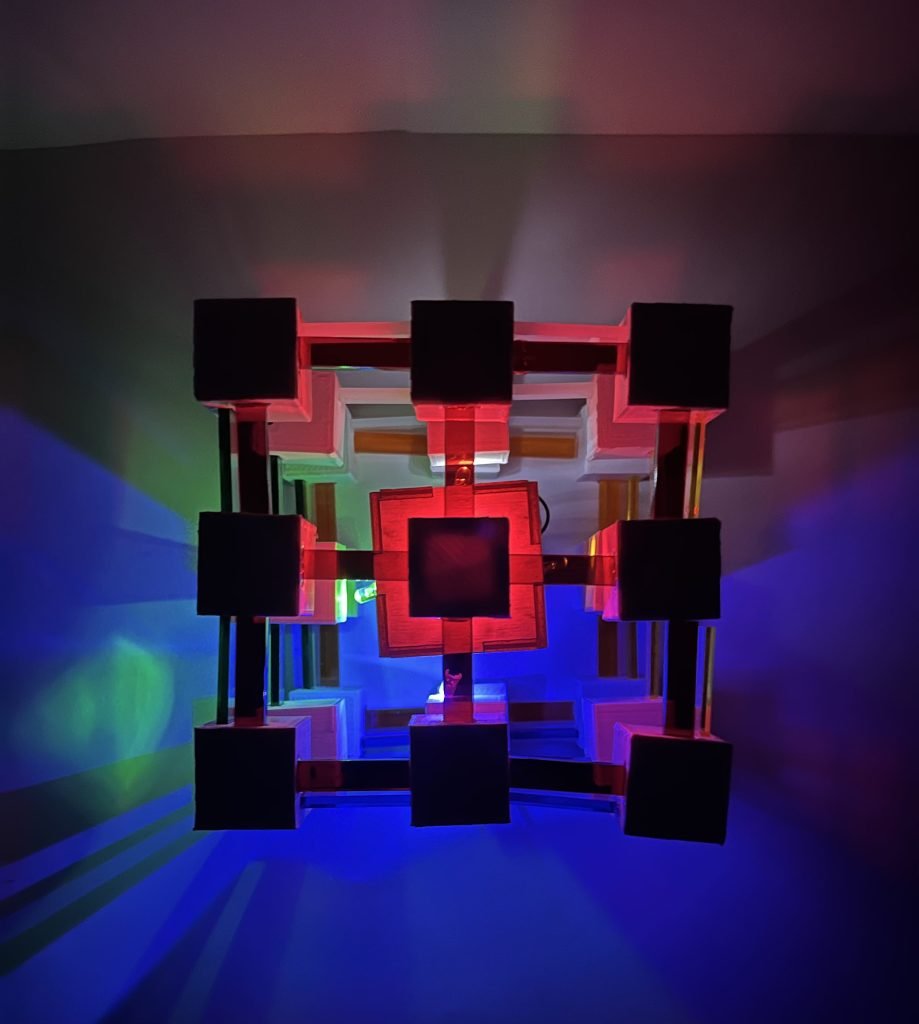

Students designed a lamp or a light installation using the bulbs provided. The design didn’t have to be a traditional light fixture. They learned how to pressure fit without using glue and 3D printing various parts to fit around their bulbs. They were required to use the 3d printer and/ or the laser cutter and to make prototypes and tests. They used Fusion 360 for technical drawings and 3D modeling.

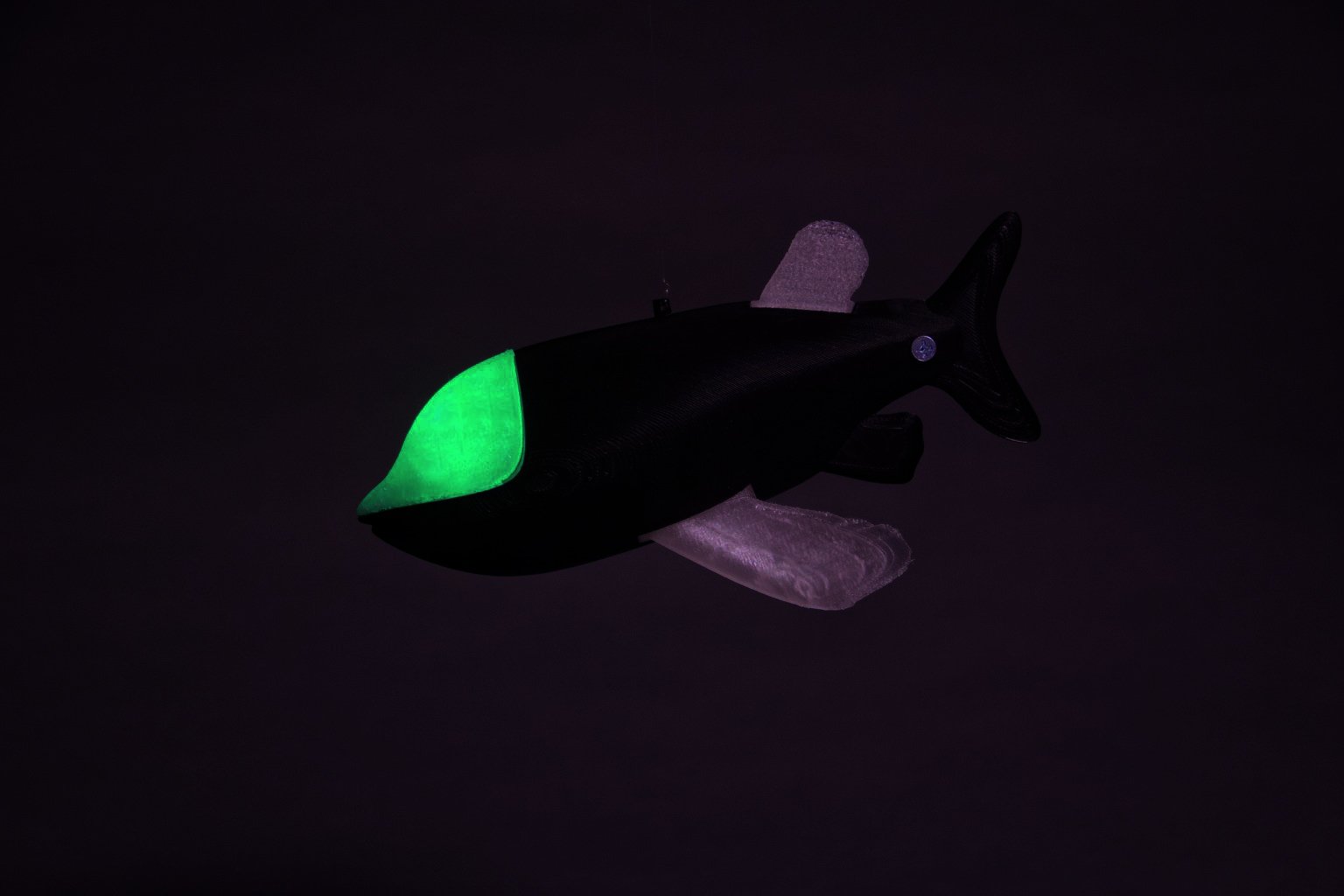

PROJECT 3 - WEARABLE/ SOFT SCULPTURE

The assignment was to make wearable or soft sculptures. Wearables were required to fit the maker or their friend in class. They could use wood, 3D printing, fabrics, and plastics. They submitted initial drawings, paper patterns, muslin(Prototype), and the final piece. Soft sculpture pieces were required to use sewing machines or other techniques we used in class, like 3D printing and CNC milling. They were required to create 3D volumes with the piece using stuffing, different ways of pattern-making 3D printing, and creating wood structures to hold softer materials. They tuned in Paper pattern, Prototype, and Final piece.

FORM 2022 wINTER

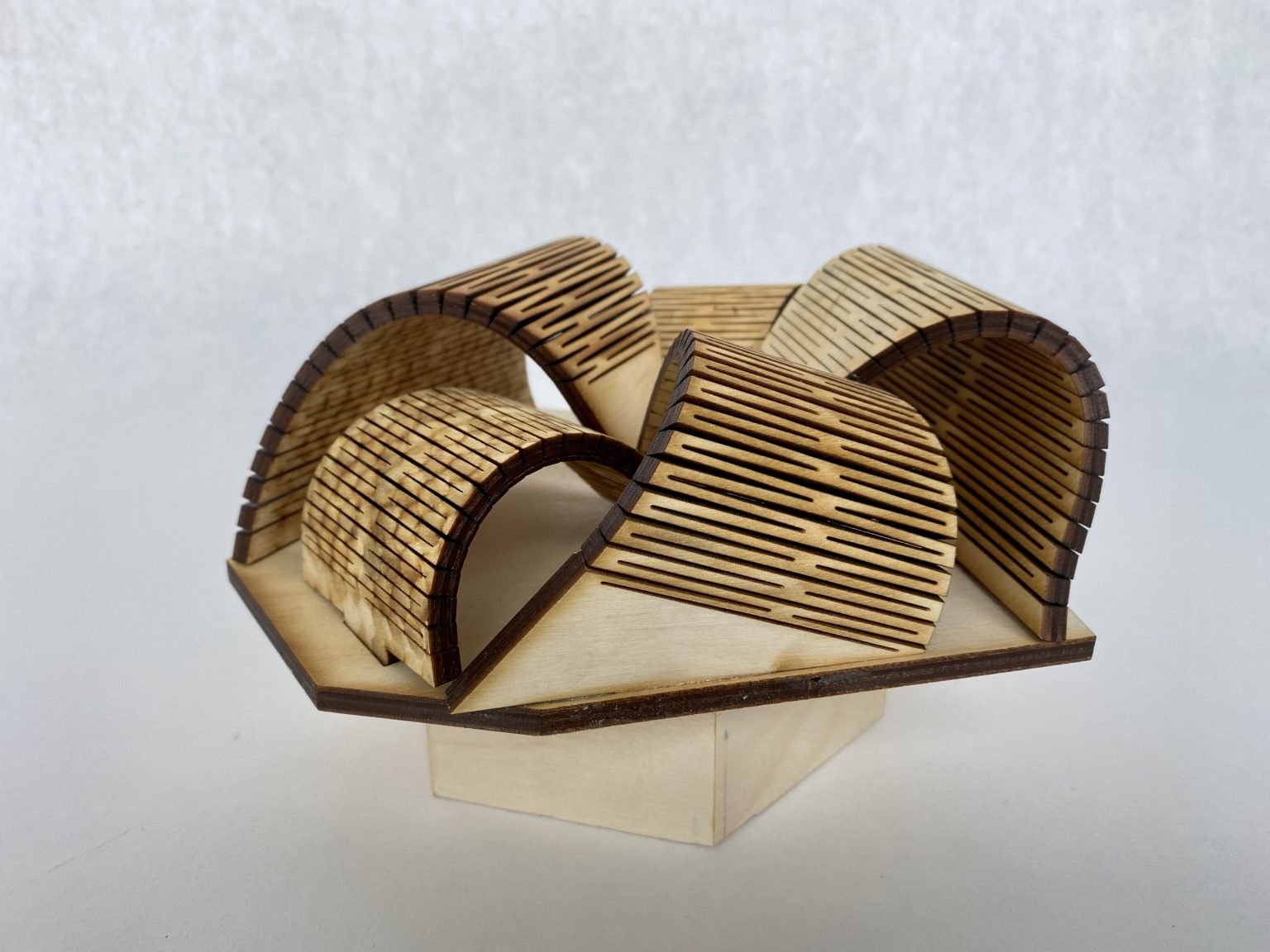

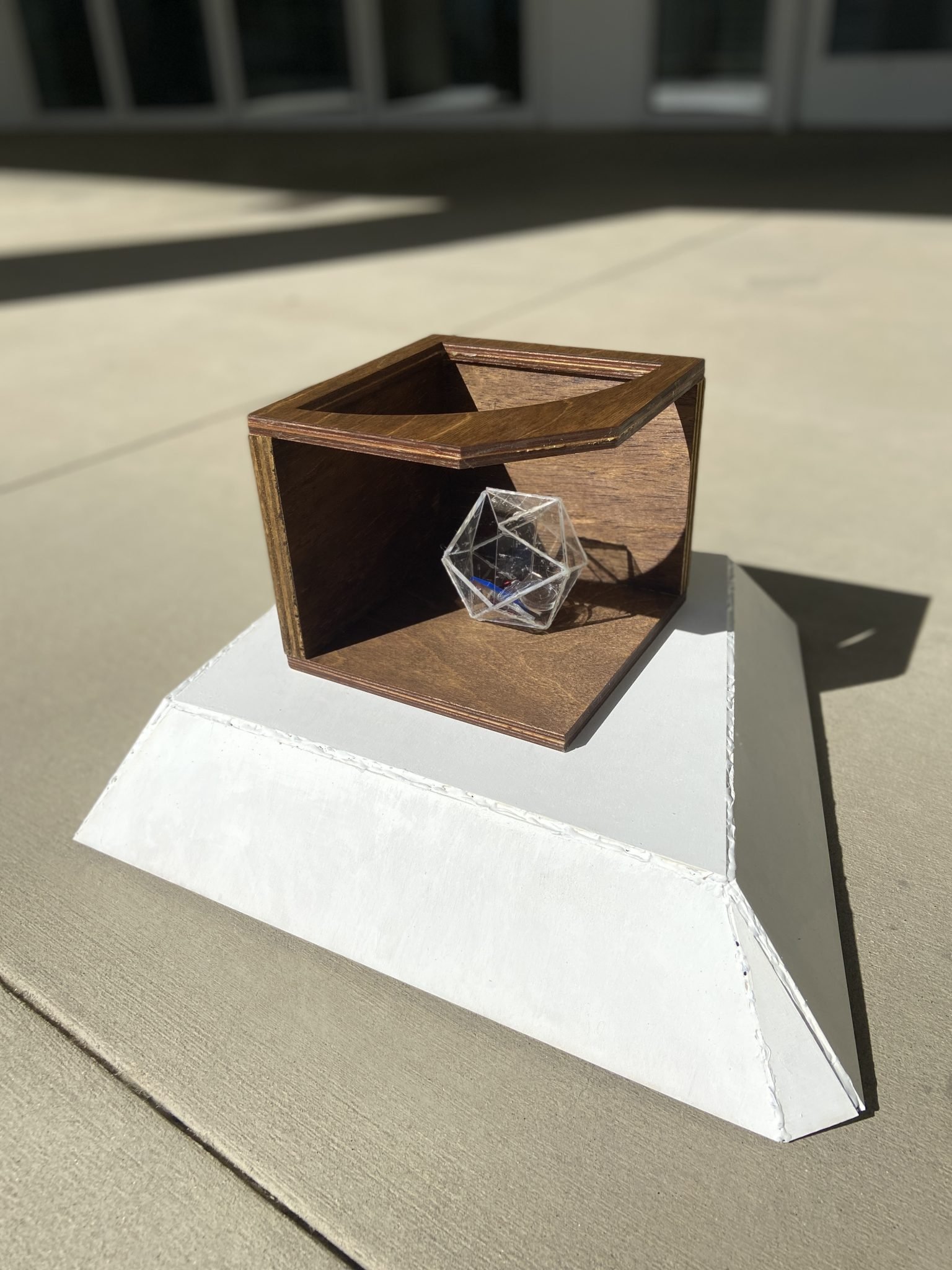

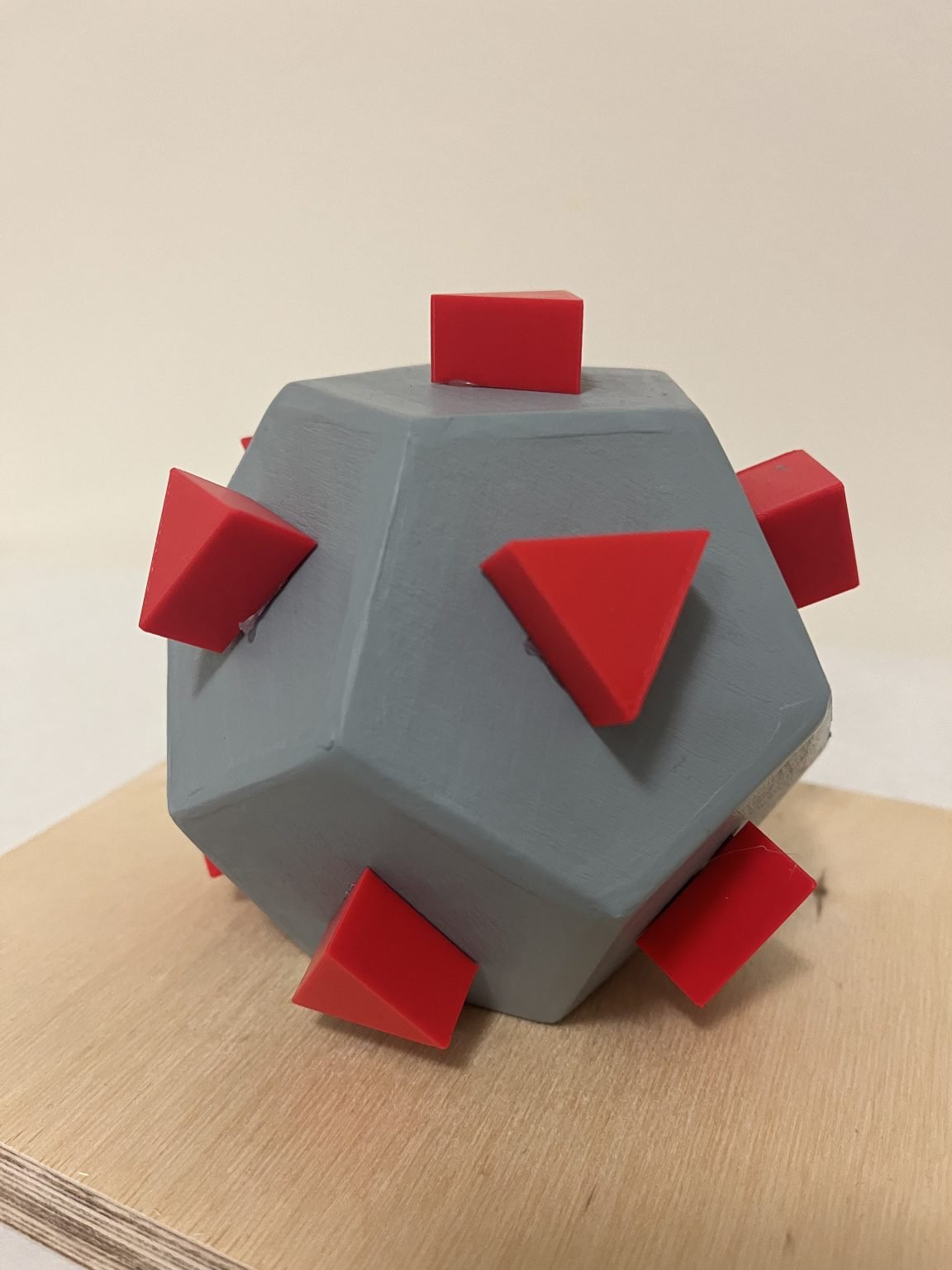

Project 1- POLYHEDRON& PEDASTAL

Goals: Develop an understanding of technical drawing/ drafting on paper and in Fusion and an understanding of the shop tools. Design a polyhedron (a geometric 3D form with only flat, straight sides) and a pedestal (a rectangular or square box) that fits the scale of your polyhedron. If you are making your polyhedron using woodworking techniques. You can think about unusual ways of creating a pedestal.

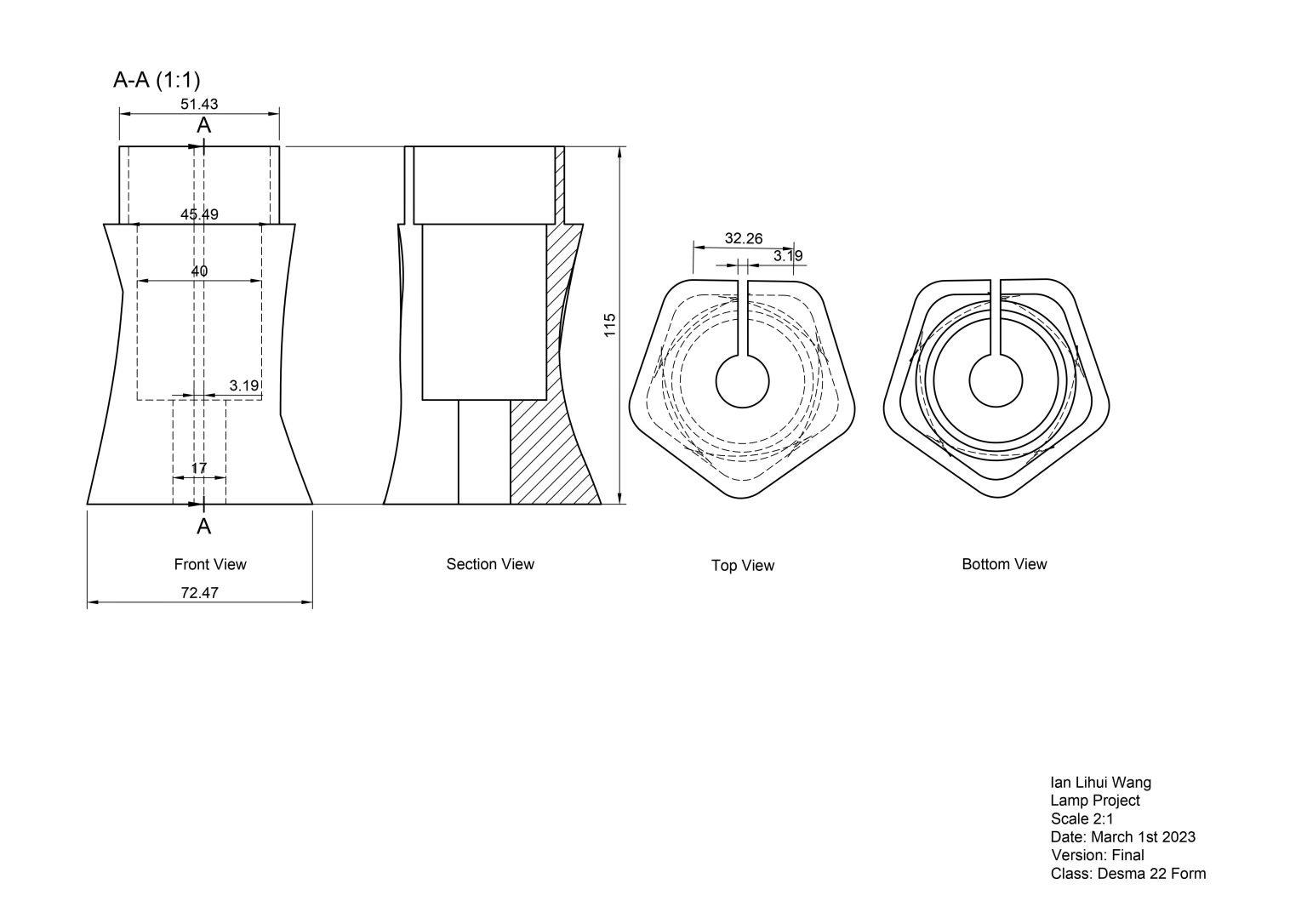

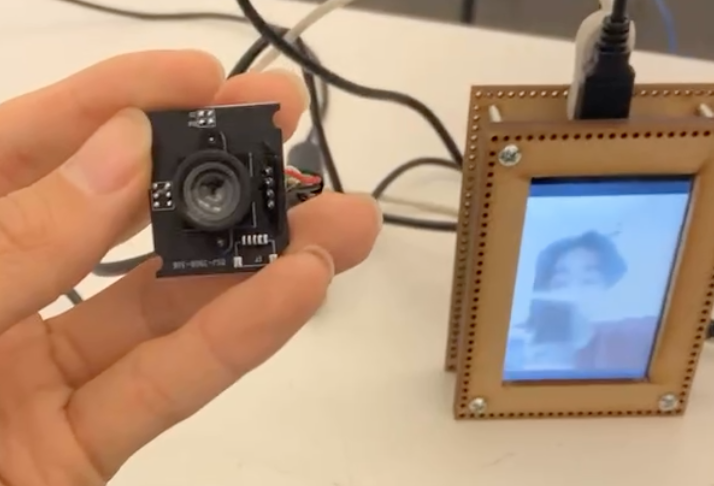

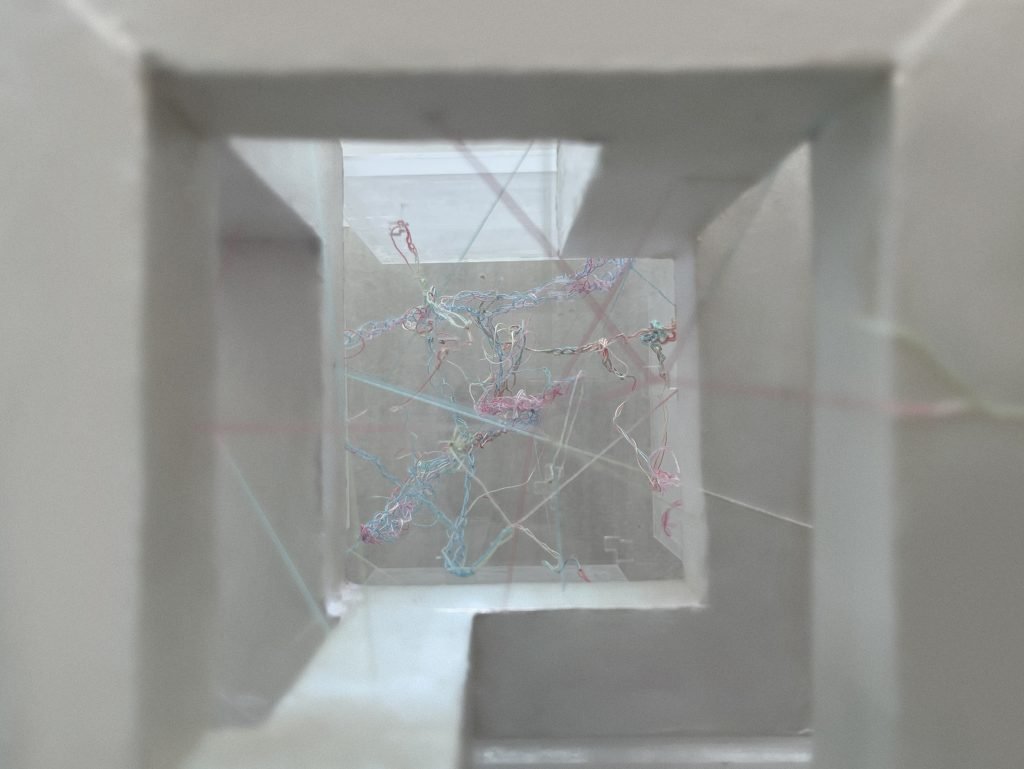

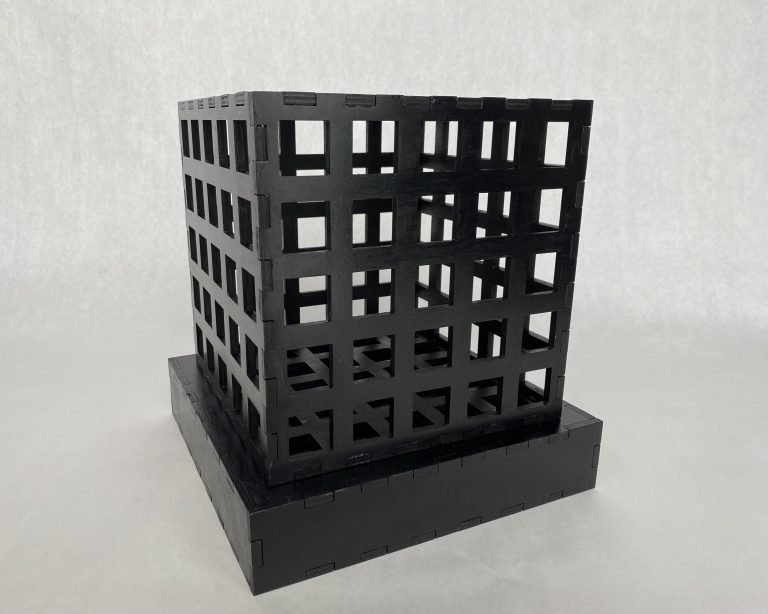

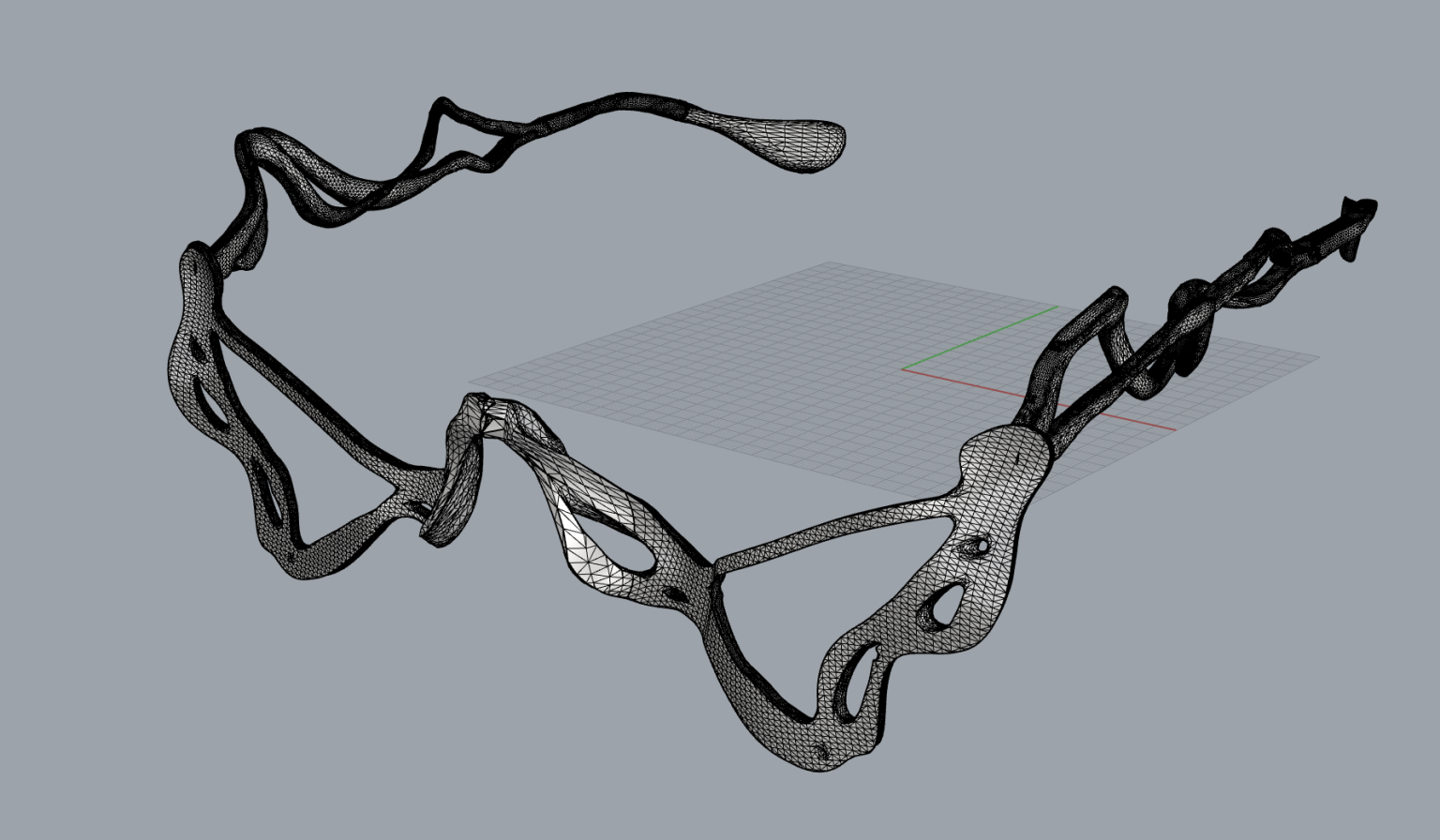

PROJECT 2 - LAMP DESIGN (Additive subtractive process)

Goals: Successfully model a form and translate that model into a 3D object using the workflows and digital fabrication tools in class. Use real-life measurements and an understanding of fit to produce an object that accounts for tolerance of the various tools. You will be provided with a light fixture. Design a unique lamp that uses a digital process to produce the body. Think about the ways that light can be modified and filtered by your form. How can your light change the space? What is the concept behind the design? Model the lamp body in Fusion 360, and use the software specific to your workflow (Illustrator for laser cuts or Cura for 3D prints). You will need to make a lamp body that connects to your light fixture through a pressure fit. You will determine the pressure fit by learning the tolerance of your fabrication tool. The lamp can be made of wood, acrylic, PLA, and other materials.

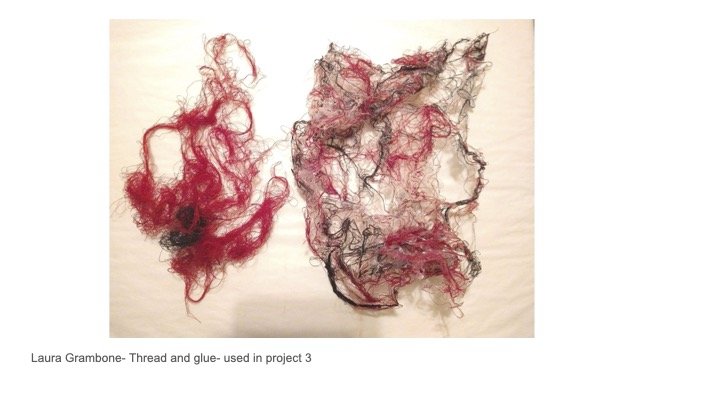

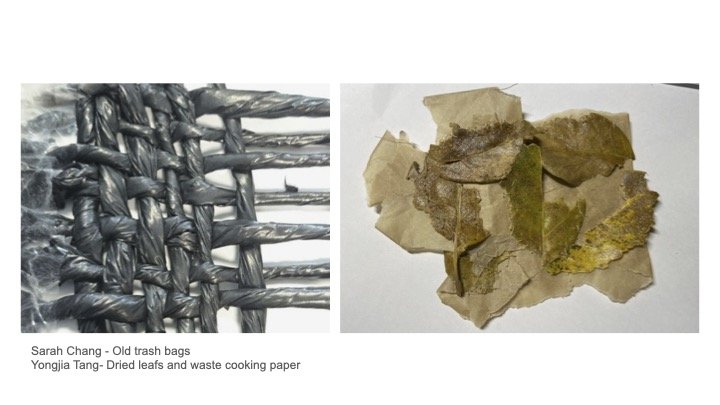

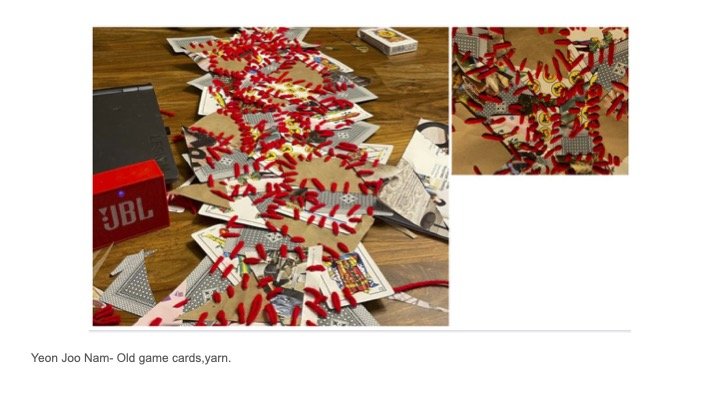

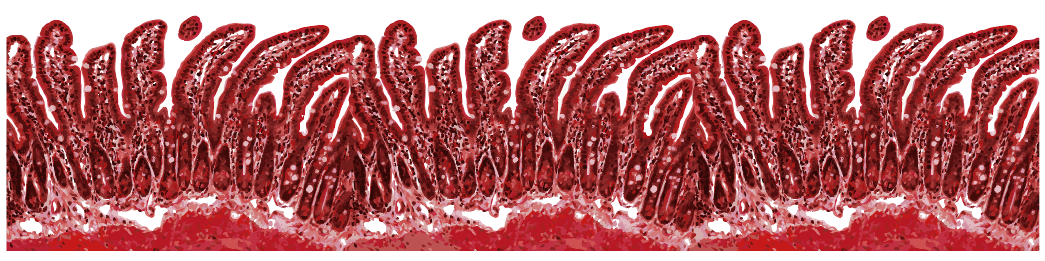

MATERIAL STUDIES

This project focuses on understanding 3D form through experimenting with materials. Students will learn how to make yardage of materials out of found objects and learn how to form these materials into objects or wearables. As students complete their assignments, the class will contemplate what it means to repurpose objects, how does this action alters the meaning of the objects, and what it means to sculpt with the newly created material.Students are encouraged to use this materials in one of their projects.

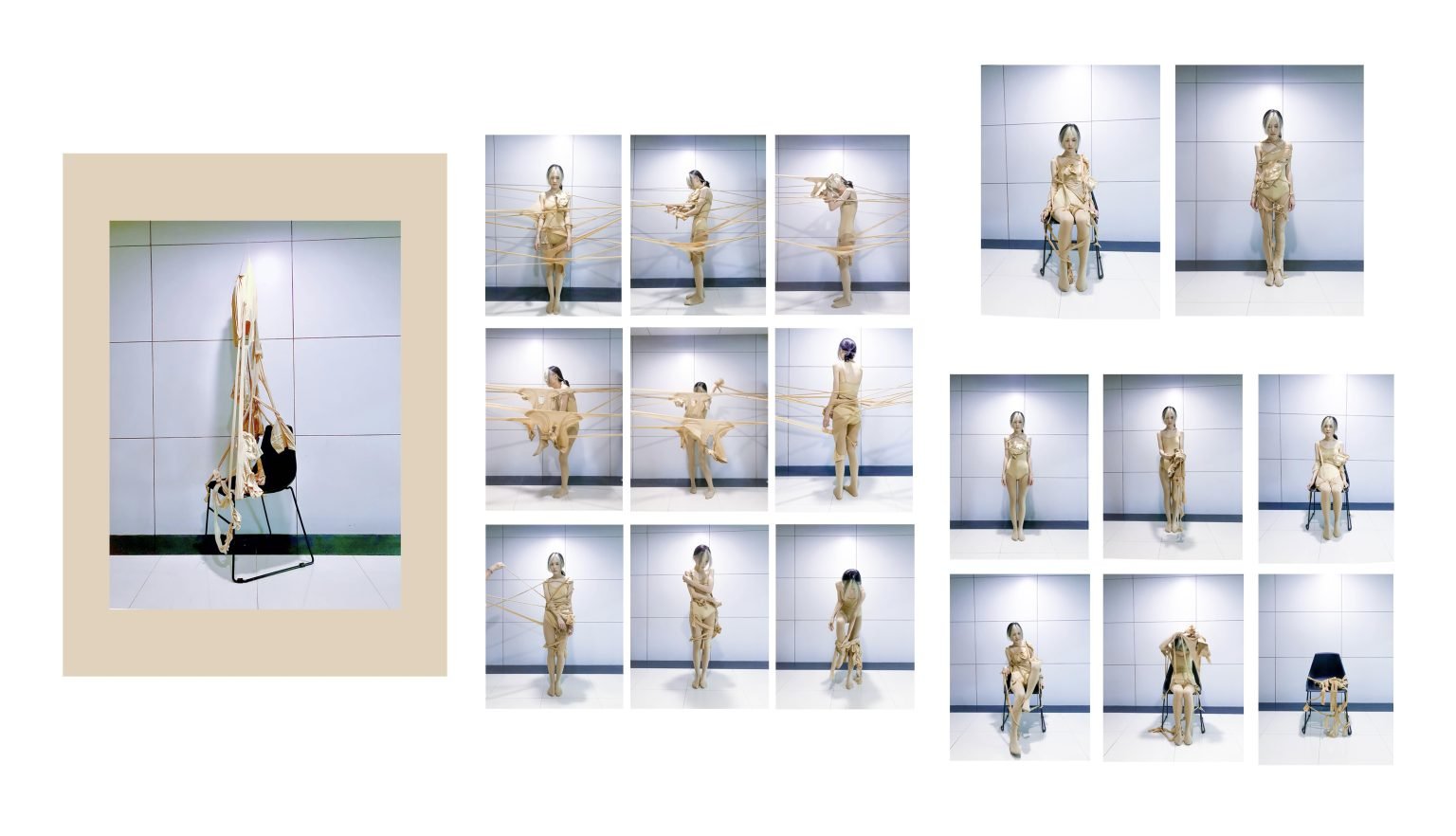

PROJECT 3 - SOFT SCULPTURE/ WEARABLES

Create a wearable that fits you (or a classmate’s) body and has a utilitarian or conceptual purpose or a soft sculture. Consider the ways this object can facilitate or inhibit motion. You are encouraged to use soft materials like the foam and cloth either alone or in combination with 3D printed, laser-cut, CNC, and other materials. When working with the foam or cloth use 2D templates or patterns to design these forms.